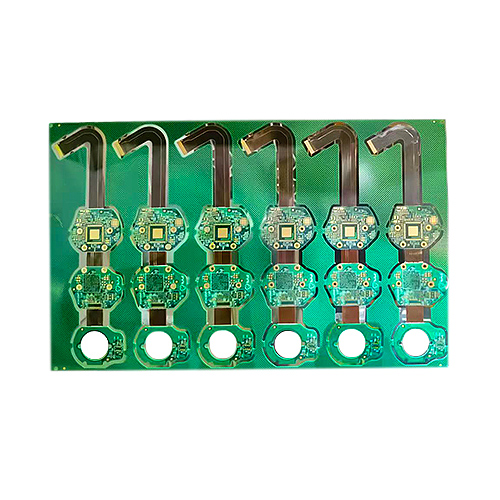

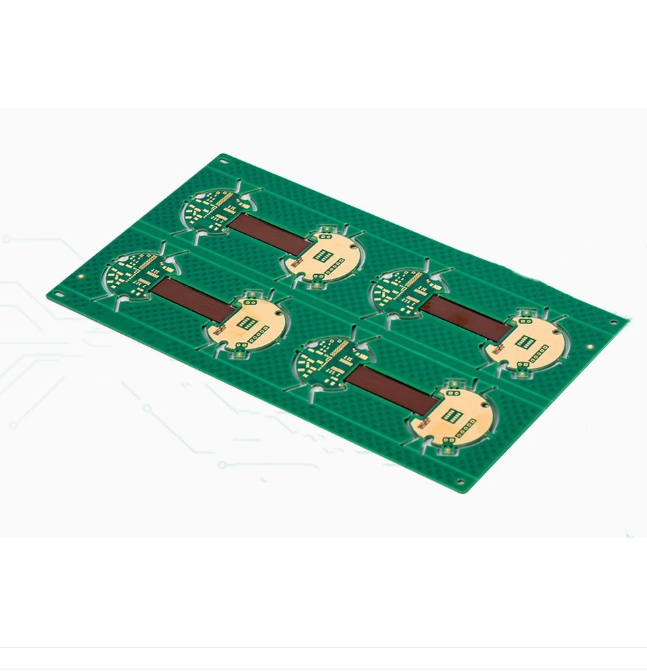

- Rigid-Flexible PCB (HIGH TG six-layer blind hole plate)

- 【Brief】:

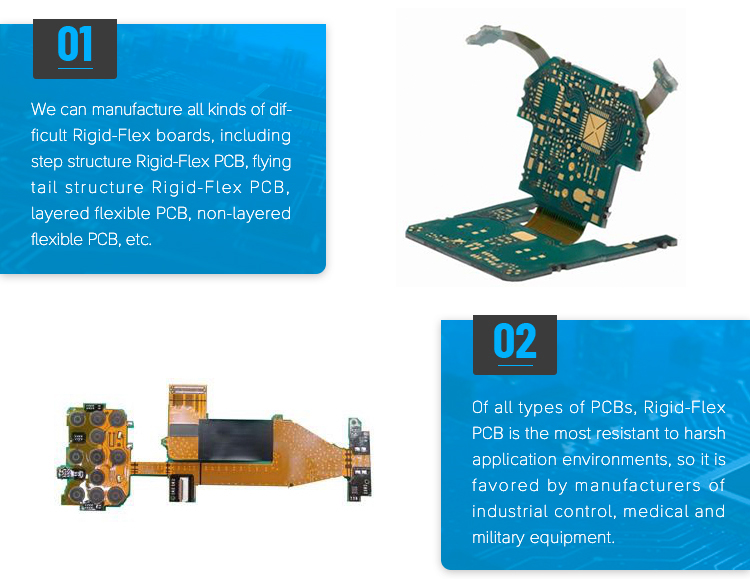

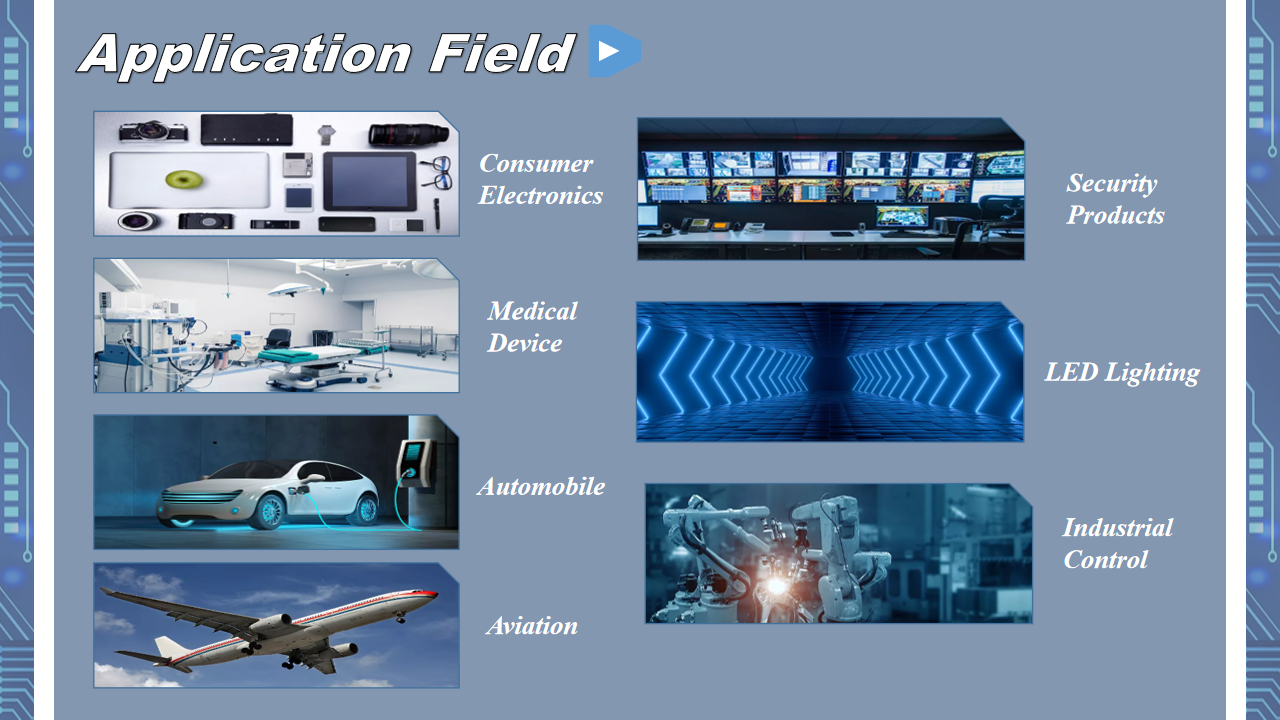

1, industrial use: including industrial, military and medical fields. These areas of product requirements for hard and soft board:

high reliability, high precision, low impedance loss, complete signal transmission quality, durability, etc.

Because the process is complex and the output is small, the production cost is high.

2, mobile phone: The application of soft and hard board in the mobile phone, common are folding mobile phone round point, image module, button and RF module.

3, consumer electronics: the soft and hard boards used by DSC and DV are the most representative.

In terms of performance, the soft and hard boards can be connected to different PCB hard boards and components in three dimensions,

which can increase the total use area of the PCB under the same line density, improve the circuit load capacity,

and reduce the signal transmission limit and assembly error rate of the contact. In terms of structure,

the soft and hard board is light and thin, and it can flex the wiring, which is of substantial help to reduce the volume and reduce the weight.

- 【Series】:Rigid-flexible pcb

Rigid-flex Mainboard PCB Board

1.Introduction of OEM Professional High Rigid-Flex PCB

Landes Circuits is capable of providing full turnkey and partial turnkey printed circuit board assembly services.

For full turnkey, we take care of the entire process, including preparation of Printed circuit boards, procurement of components,

online order tracking, continuous monitoring of quality and final assembly. Whereas for partial turnkey, the customer can provide the PCBs and certain components,

and the remaining parts will be handled by us.

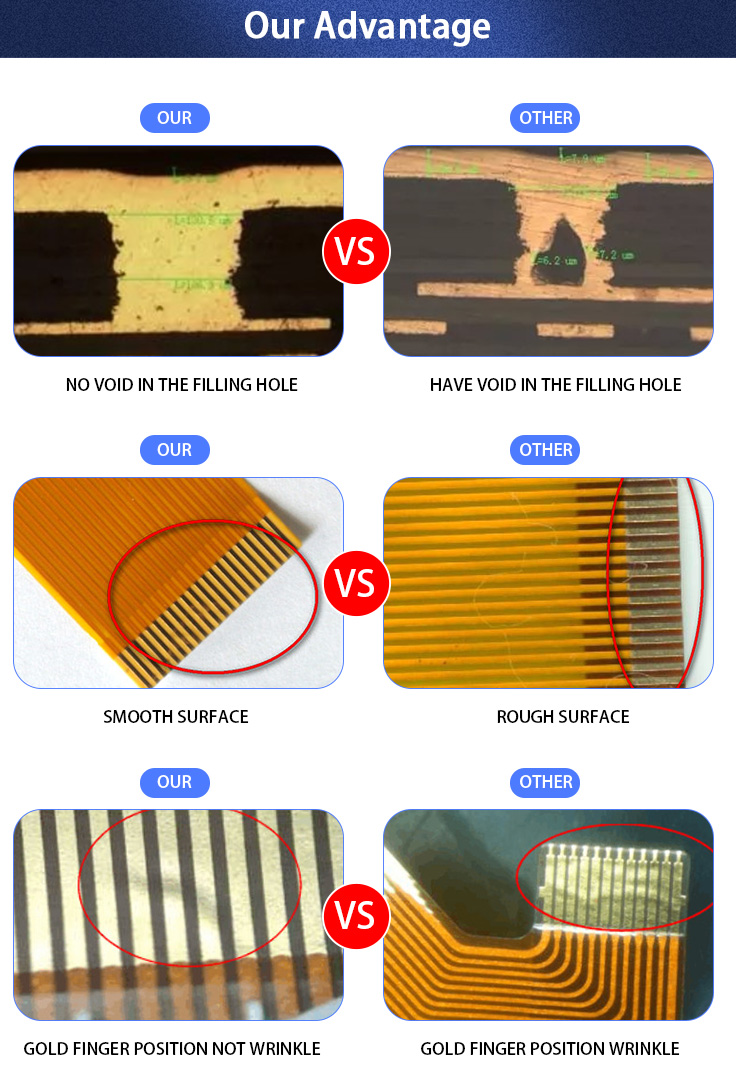

2.Features-Our Products Advantage

1. Over 10 years experience manufacturer in PCB Assemble and PCB field.

2. Big scale of producing makes sure that your purchase cost is lower.

3. Advanced production line guarantees stable quality and long life span.

4. Produce almost any PCB as your requirement.

5. 100% test for all customized PCB products.

6. One-stop Service ,we can help to purchase the components

Landes Circuits Co., Limited

FPC Technology and Capabilities

Material

FR4, Polyimide / Polyester

Counts

Flex: 1~8L; Rigid-Flex: 2~8L

Board Thickness

Min.0.05mm; Max. 0.3mm

Copper Thickness

1/3 oz — 2 oz

CNC Drill Size (Max)

6.5mm

CNC Drill Size (Min)

Flex: 0.15mm

Holes Location Tolerance

±0.05mm

Coverlay Drill Size (Min)

0.6mm

Hole to Coverlay Opening Windows (Min)

0.15mm

Min Line Width / Spacing

0.1/0.1mm

Copper Thickness on Hole Wall

Flex:12-22μm

Min Pad Size

φ0.2mm

Etch Tolerance

Finished line width tolerance ±20%

Pattern Registration Tolerance

±0.1mm (Working Panel Size: 250*300mm)

Coverlay Registration Tolerance

±0.15mm

Solder Mask Registration Tolerance

±0.2mm

Solder Mask to PAD

Non photosensitive: 0.2mm

Photosensitive: 0.1mm

Min. Solder Mask Dam

0.1mm

Misregistration Tolerance

±0.30mm

for Stiffener, Adhesive, Glue paper

Surface Finish

Plating Ni / Au ; Chemical Ni / Au ; OSP

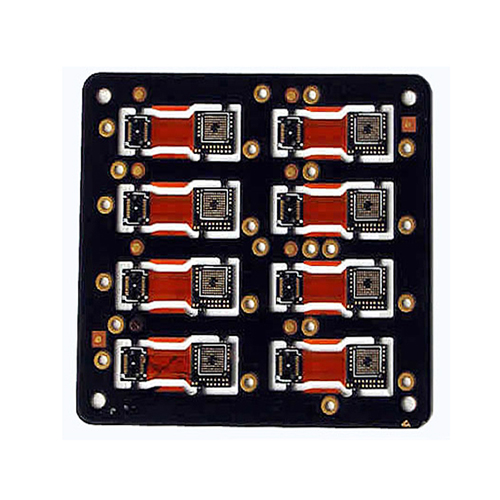

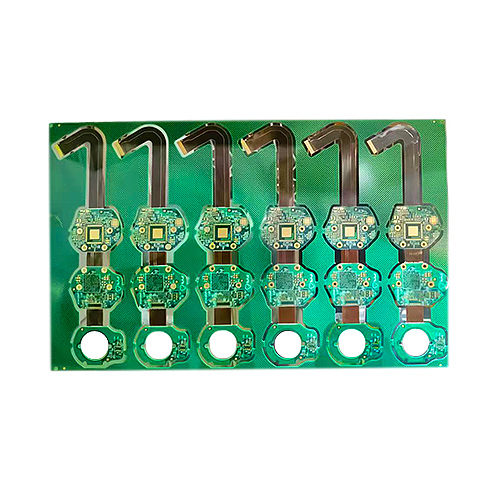

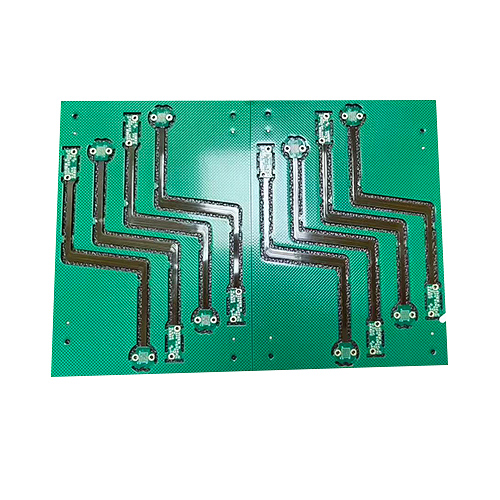

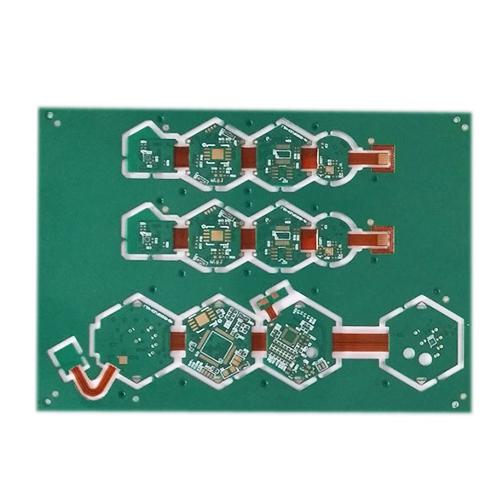

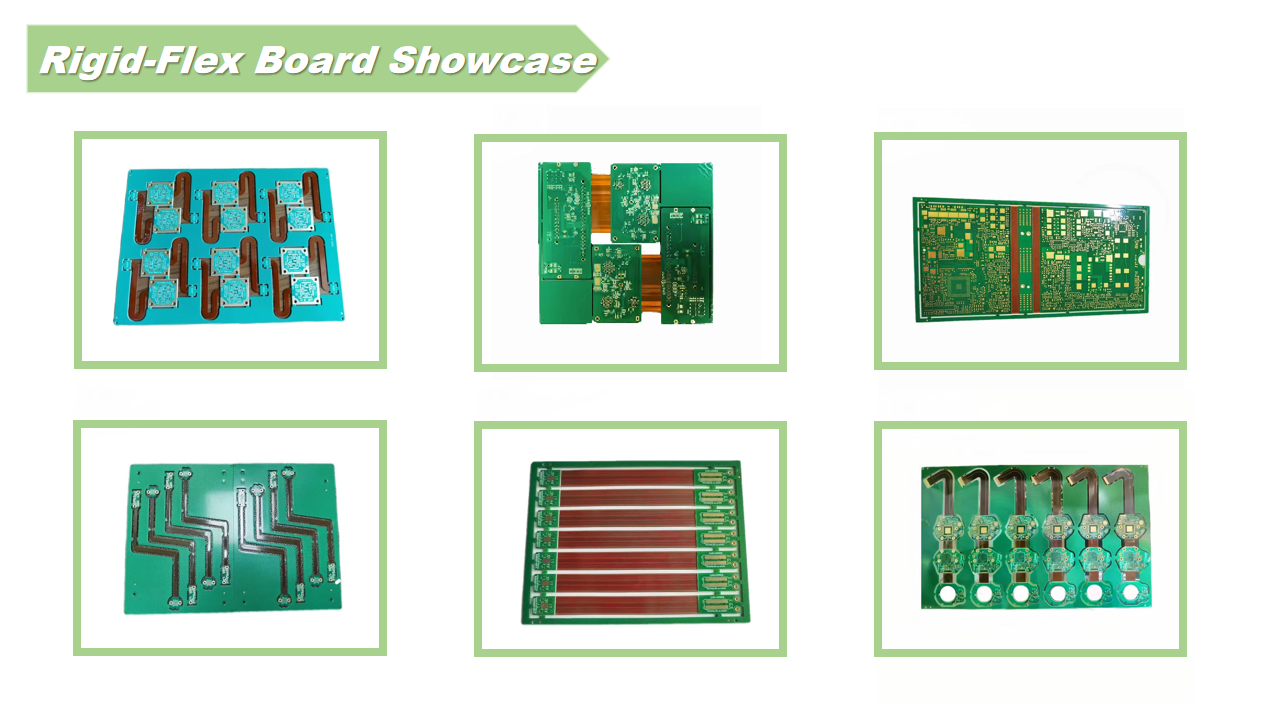

4. Related Rigid-Flexible board

5.Application

6.Workshop

7.Certificates

We have set a separated department where exclusive production planner will follow your order production after your payment, to meet your pcb production and assembly requirement.

We have below qualification to prove our pcba.